The premise of Plating, as initially portrayed by the AO, has been:

- anatomic break decrease and obsession,

- inflexible crack steadiness (pressure or bracing)

- conservation of the blood supply to the delicate tissues and bone through cautious taking care of and delicate decrease strategies, and

- Early and safe preparation of the area.

These locking compression plate manufacturers level standards have advanced, by which the current methodology is to keep up with the blood supply to the delicate tissues and bone as the main part of break care.

Traditional Locking Plates: anatomic break reproduction

Since traditional Plating depends on the grating produced between the plate and bone, exact plate forming is expected to match the anatomic bone shape.

In traditional Plating, whether the bone parts are accurately diminished preceding plate application, crack disengagement will result if the plate doesn’t come by.

Large fits the bone as the screws are fixed a deficiency of decrease may then happen (loss of essential decrease). Moreover, under a hub load postoperatively, assuming the shear powers are more noteworthy than the frictional powers between the plate and bone, loss of the obsession might happen due to flipping of the screws (loss of optional decrease).

Once more, because the locking compression plate manufacturers level plate is compacted deep down the surface, the periosteum is packed under the plate region, decreasing or, in any event, interfering with blood supply deep down.

The outcome can be deferred bone mending because of impermanent osteoporosis under the plate.

At long last, in cases with diminished bone quality, for example, osteoporotic bone, who can’t fix screws adequately to acquire the pressure expected to help the bone.

This might cause relaxing of the screws and loss of security, with at last a deficiency of the decrease.

However, standard Plating accomplishes great outcomes in great quality bone and breaks generally fixed with slack screws to accomplish direct bone mending despite these indicated limits.

- Locked Plating – spanning break reproduction

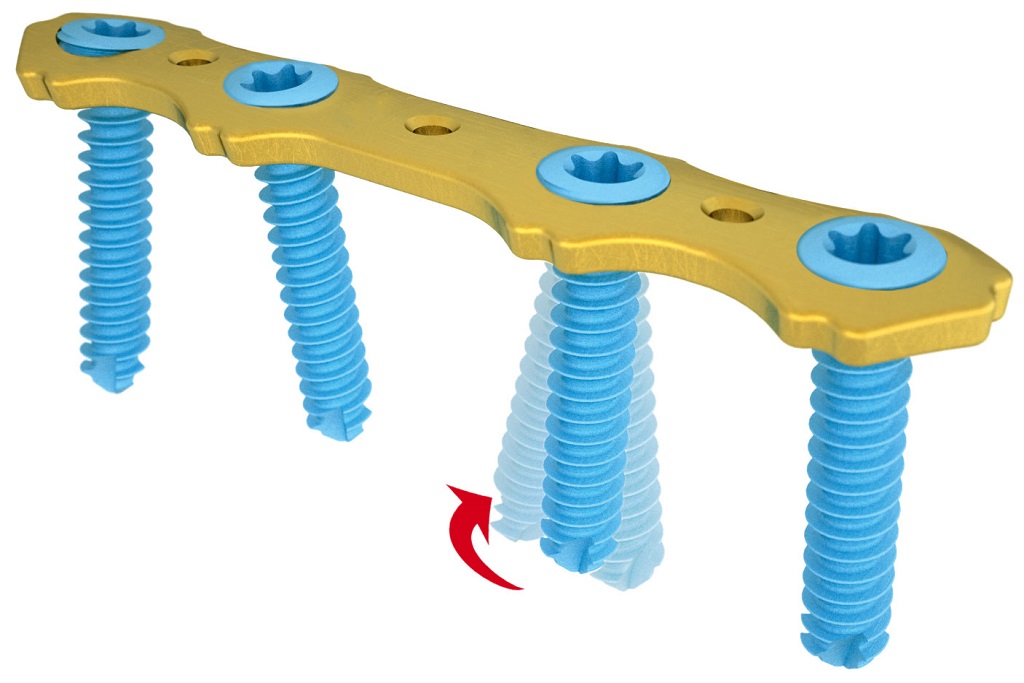

- This strategy locks compression plate manufacturers’ level to the plate, shaping a fixed-point development. Bone mending is accomplished in a roundabout way by callus arrangement.

- When the locking screws connect with the plate, no further fixing is conceivable; hence, the embed secures the bone fragments their relative positions no matter the level of decrease acquired.

- The plate’s formation limits the hole between the plate and the bone; notwithstanding, a careful fit isn’t required for embed strength. This element is particularly favorable in insignificantly or less obtrusive plating methods because these strategies don’t permit careful shaping of the plate deep down the surface.

- By locking the screws to the plate, the hub power is sent over the length of the plate, and the danger of an auxiliary loss of the intraoperative decrease is diminished.

- At last, securing the screw in the plate doesn’t produce extra pressure; accordingly, the periosteum will be safeguarded, and the blood supply deep down saved.

- A fixed-point development benefits osteopenic bone or multi-fragmentary breaks where customary screw buy might become compromised.

- The significant change in the hypothesis of crack obsession happened with the improvement of locked spanning inner obsession with the PC-Fix (Synthes). While utilizing this embed and the hypothesis of “spanning plate osteosynthesis,” crack association happened by optional, rather than essential bone recuperating similarly as with inflexible inner obsession.

- This underlying locked plate configuration made the primary screw-plate single composite pillar build similar to a traditional outside fixator.

The Less Invasive Skeletal Stabilization framework created a superior locking compression plate manufacturers level framework for metaphyseal cracks (LISS, Synthes).

A few trial studies showed the expanded security and advantages of safeguarding fragmentary blood supply utilizing the LISS framework.

Further refinements to the PC-Fixidea prompted the plan and production of the locked pressure plate (LCP, Synthes).

The LCP gave rakish and pivotal security, which again diminished or dispensed with the requirement for accurate plate forming, in this way limiting the danger of essential loss or decrease.

Also, the mix screw-opening permitted regular screw obsession, empowering the specialist to apply the most proper obsession technique.

As of now, various makers have locking plate frameworks accessible. The various ideas between the unique frameworks in veterinary medication are introduced here: LCP (SynthesVet), SOP™ (Orthomed), ALPS (Kyon), and Fixin (TraumaVet).

For instance, different producers, for instance, Securos™ and NGD, have comparative properties to the LCP and won’t be discussed.

Locking screws give the capacity to make a fixed-point develop while using the natural plating procedures.

Locking screws don’t depend on plate/bone pressure to keep up with steadiness, yet work in basically the same manner to different little calculated cutting edge plates. The idea of screw obsession was proposed, further limiting the harm to vascularity.

From the mechanical viewpoint, bicortical screw obsession has been involved with customary plate obsession as both cortices are expected to accomplish adequate solidness to forestall pullout (screw security and burden move are achieved at two focuses along the screw: the all-over cortices) – accordingly keeping up with rubbing between the plate and bone.

Locking compression plate manufacturers’ levels are proposed to give adequate strength and burden move just close to the cortex because of the strung association between the plate and the screw.

This last idea has been addressed in little creatures because of the presence of exceptionally flimsy cortices; subsequently, bicortical screw obsession, or twofold plate obsession (inverse or symmetrical with monocortical screw obsession), is as of now suggested.

LCP (SynthesVet)

The LCP plates have mixed locking and pressure openings or purported “Combi opening.”

This permits the plate to be applied with either fixed point securing fastening the strung piece of the Combi opening or standard cortical screws set in the unique pressure unit (DCU) some portion of the Combi opening.

Likewise, these plates have around a “stacked opening” in at least one position.

Conclusion

The circular opening limits of the locking compression plate manufacturers’ angulation level.

Furthermore, it doesn’t allow any pressure to be applied; it is utilized toward the finish of the plate where there is restricted space to put the Combi opening.

The locking opening has strings (with a Morse tighten) that match the screw head.

- Essential Guidelines on intake of Iron Sucrose

- How To Use Orthopedic Implants?

- How To Improve Poor Leg Circulation

For More Latest Health Updates and Information about Locking Plates, Visit Ebuzz Spider.